Concrete Spall Repair

Lucky you live Hawaii! (Even if you do dwell or work in a concrete structure)

Many of Hawaii’s buildings are of concrete or concrete block construction. Unfortunately from a corrosion viewpoint, steel reinforcing is an integral structural component of each. Hawaii’s salt laden environment (and especially our cooling trade winds that pickup ocean spray) promotes the intrusion of chloride (i.e., salt) into the concrete. While not a necessary ingredient for rusting to occur, salt certainly speeds up the process. Witness our rusting cars, especially when they are parked on the windward side of our islands and close to the ocean. Embedded reinforcing steel in Hawaii's buildings rusts for the same reason.

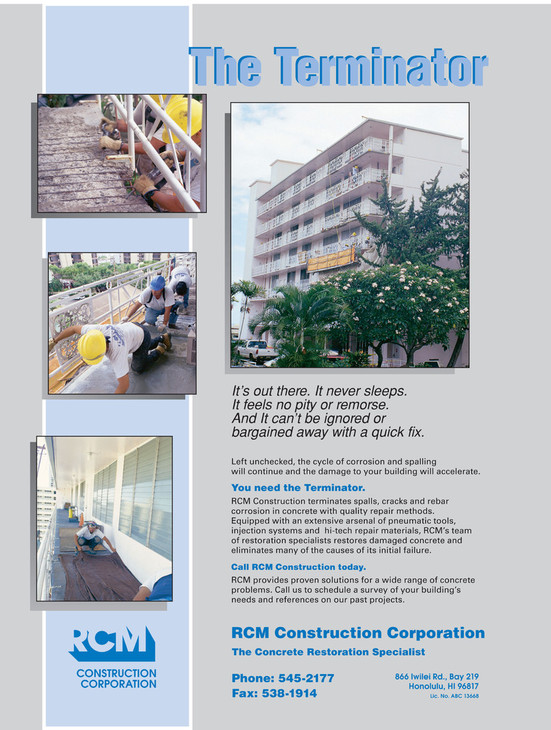

Rust occupies more volume than the originating steel, thus when the expansive forces of the rusting rebar exceeds the tensile or confining strength of the surrounding concrete, the concrete pops or delaminates or spalls. Depending upon the location of the spalling concrete, a life safety situation may result.

Rusting rebar is especially common along the edges of our exposed concrete corridors and lanais and at the corners of concrete block walls. Rusting of embedded rebar is most always the cause of concrete spalling. Most of us have seen spalling concrete, chunks of which can fall on a person or a vehicle. Fortunately, it is rare that a person is standing or walking below at the same time a chunk of concrete falls from above. Nonetheless, spall repair should not be put off. Both the continuing delamination and subsequent repair cost only increases.

The repair is conceptually easy – remove the delaminated concrete, chip around the exposed rebar to remove chloride contaminate concrete, apply corrosion inhibitors and rusts converters, add a bonding agent, and patch.

While conceptually easy, the actual repair is technically challenging on several levels and not something that should be an afterthought when painting a building. An important key is to ‘chase’ the rusted rebar, including removing chloride-contaminated concrete from behind the rebar as well as several inches to the right and left in order to expose clean rebar. This is an often omitted step, especially when performed as part of painting operations due to the lack of pneumatic chipping equipment and often due to lack of technical skills. It is also the reason that many spall repair efforts come up short. Chipping behind rebar is hard work. If this step is not performed properly, spalling will reoccur sooner than later.

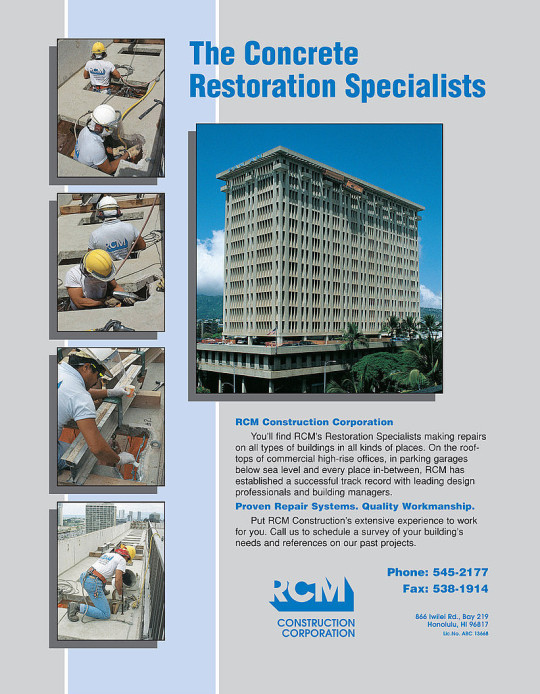

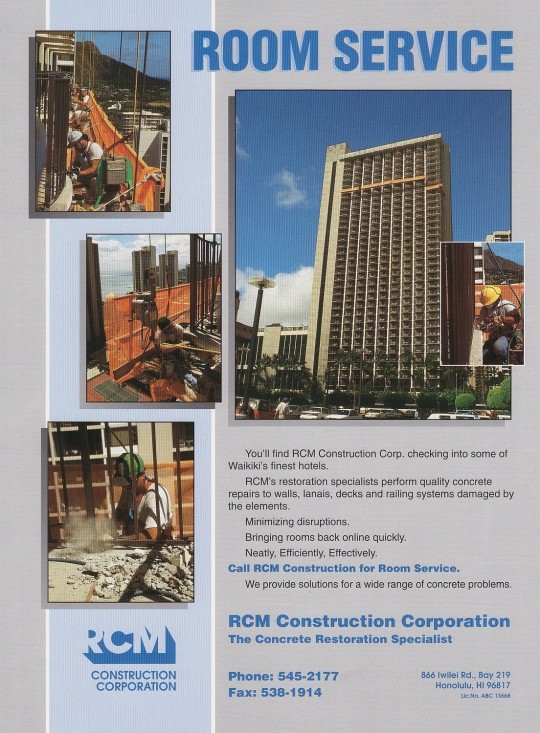

We perform both large jobs (hotels, condominiums and office buildings) and small jobs (residences as well as individual concrete lanais).

The following illustrations are from some of our prior advertisements showing a sampling of our larger concrete spall repair projects.

While they emphasize larger projects, we perform spall repair on many, many smaller jobs. In fact the majority of our projects are small jobs.